In today’s rapidly evolving manufacturing and electronics landscape, precision, efficiency, and reliability are more important than ever. Engineers, technicians, and hobbyists alike face the ongoing challenge of selecting the right equipment and tools to streamline production, ensure product quality, and minimize costly errors. From circuit board assembly to advanced CNC machining, having the appropriate instruments can make the difference between a flawless project and repeated setbacks.

Among the wide array of devices available, certain tools stand out for their innovation and effectiveness, offering solutions that blend cutting-edge technology with practical usability. In this article, we explore four essential tools that have become indispensable in modern workshops and laboratories: the PoStep25-256, a high-performance stepper motor driver; the PCB tester, a critical instrument for ensuring circuit integrity; the ToolSens8, an advanced sensing device for tool monitoring; and the CNC tool setter, a device that guarantees precision in machining operations.

By examining each of these tools in detail, we will uncover how they function, why they are important, and the specific advantages they bring to their respective fields. Whether you are an experienced engineer or a newcomer eager to optimize your workflow, understanding these technologies will provide valuable insights into achieving greater accuracy and efficiency in your projects.

What is the PoStep25-256 and why is it important in modern motion control applications?

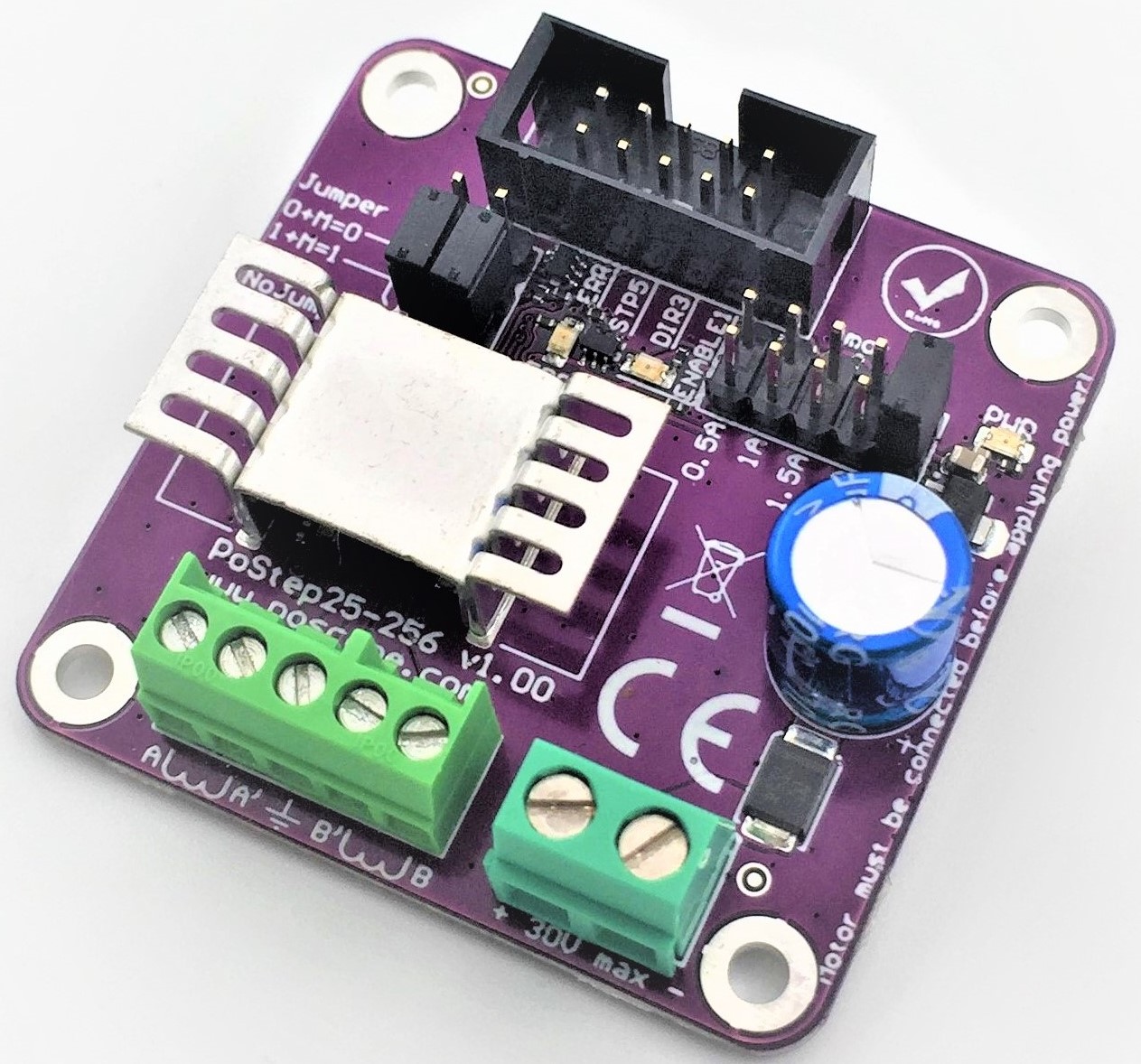

The PoStep25-256 is a high-performance stepper motor driver that has quickly become a preferred choice for engineers and hobbyists seeking precision and reliability in motion control systems. At its core, the PoStep25-256 is designed to control stepper motors with exceptional accuracy, providing smooth movement and reducing vibrations that are common in less advanced drivers.

Unlike traditional stepper motor controllers, the PoStep25-256 employs sophisticated microstepping technology, allowing it to divide each full step of a motor into 256 microsteps. This capability dramatically increases positioning resolution, making it ideal for applications where precise motion is critical, such as 3D printing, CNC machinery, robotics, and automated manufacturing systems.

One of the key advantages of the PoStep25-256 is its ability to maintain high torque even at low speeds, a feature that many standard drivers struggle to deliver. By optimizing current control and incorporating intelligent step smoothing algorithms, the PoStep25-256 ensures that motors operate quietly and efficiently, which not only improves performance but also extends the lifespan of mechanical components.

This makes the PoStep25-256 particularly valuable in environments where continuous operation and reliability are paramount. Users have noted that integrating the PoStep25-256 into existing systems often results in a noticeable reduction in mechanical wear and energy consumption, underscoring its efficiency and cost-effectiveness.

Another aspect that sets the PoStep25-256 apart is its versatility. The driver supports a wide range of stepper motors and can be configured through intuitive software interfaces, allowing precise tuning of parameters such as acceleration, deceleration, and current limits. This flexibility enables the PoStep25-256 to adapt to various setups, from compact desktop devices to large industrial machinery. Additionally, the PoStep25-256 often incorporates protective features against overheating, short circuits, and voltage spikes, ensuring both safety and reliability in demanding operational conditions.

For professionals working in advanced manufacturing or automation, the PoStep25-256 offers an ideal combination of precision, durability, and configurability. By allowing fine control over every movement of a stepper motor, it enhances the overall accuracy of processes and minimizes the risk of errors.

When integrated into a workflow that includes tools such as PCB testers, CNC tool setters, and automated sensing devices like the ToolSens8, the PoStep25-256 contributes to a seamless and highly efficient production environment. In essence, it is not merely a motor driver but a crucial component in achieving the highest levels of motion control performance.

What is a PCB tester and why is it essential for electronics manufacturing?

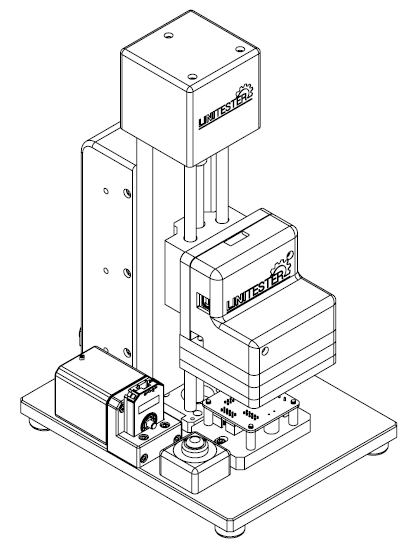

A PCB tester is a specialized device used to assess the integrity and functionality of printed circuit boards (PCBs) before they are incorporated into larger electronic systems. In modern electronics manufacturing, ensuring that each PCB is free from defects such as short circuits, open circuits, or misaligned components is critical, as even minor faults can lead to device failure or reduced performance. The PCB tester provides engineers and technicians with a reliable means of detecting these issues early, saving both time and resources that would otherwise be spent on troubleshooting finished assemblies.

The primary function of a PCB tester is to evaluate the electrical connectivity of a board. By applying test signals to various nodes on the PCB and measuring the response, the tester can determine whether each trace, component, and connection meets the required specifications. Advanced PCB testers can also perform automated optical inspections, checking for missing components, soldering errors, or deviations from design tolerances. This level of scrutiny is particularly important in high-precision industries, such as aerospace, medical devices, and telecommunications, where the reliability of each PCB is paramount.

Modern PCB testers are designed to be versatile and user-friendly. Many models allow for rapid switching between different test protocols, accommodating a wide variety of PCB layouts and component types. Some testers even integrate with software systems to log results, analyze trends, and identify recurring defects, making it easier to improve production processes over time. By incorporating a PCB tester into the manufacturing workflow, engineers can reduce the likelihood of defective boards reaching the assembly stage, which in turn minimizes costly rework and ensures higher overall product quality.

The importance of a PCB tester extends beyond manufacturing into research and development. During the prototyping phase, a PCB tester can quickly verify the functionality of new designs, allowing engineers to identify design flaws and implement corrections before mass production. This reduces the risk of releasing faulty products and accelerates the development cycle. Additionally, PCB testers work in tandem with other tools, such as the PoStep25-256 for motion systems, CNC tool setters for machining components, and the ToolSens8 for monitoring assembly tools, creating a comprehensive ecosystem that maximizes efficiency and precision.

Ultimately, a PCB tester is more than just a diagnostic device—it is a cornerstone of quality assurance in electronics production. By providing fast, accurate, and reliable testing of printed circuit boards, it ensures that every component functions correctly, minimizes downtime caused by defects, and supports the delivery of high-quality electronic products. For anyone involved in electronics manufacturing, integrating a PCB tester into the workflow is essential for achieving consistent, dependable results and maintaining a competitive edge in today’s fast-paced industry.

What is the ToolSens8 and how does it enhance precision in modern machining?

The ToolSens8 is an advanced tool monitoring device designed to provide real-time feedback on the condition and performance of cutting tools in manufacturing environments. In CNC machining and other precision operations, the performance of a tool directly affects the quality of the final product, the efficiency of production, and the longevity of the machinery. The ToolSens8 addresses these critical needs by offering accurate, instantaneous monitoring of tool wear, vibration, and alignment, ensuring that each machining process is executed with maximum precision.

One of the key benefits of the ToolSens8 is its ability to detect subtle changes in a tool’s condition before they become significant problems. By continuously measuring parameters such as cutting forces and spindle vibration, the device can identify early signs of tool wear, misalignment, or damage. This proactive approach allows operators to replace or adjust tools before they compromise part quality or cause machine downtime.

In contrast, traditional methods of tool inspection often rely on scheduled maintenance or visual checks, which can be less accurate and sometimes fail to catch developing issues. The ToolSens8’s intelligent monitoring system ensures that every tool operates within optimal parameters, enhancing overall productivity and reducing material waste.

Another advantage of the ToolSens8 is its integration with CNC machinery and other automation systems. The device can communicate directly with machine controllers, providing real-time data that can be used to adjust machining parameters on the fly. This dynamic feedback loop enables operators to maintain consistent cutting quality even under varying load conditions or complex geometries.

Furthermore, the ToolSens8’s data logging capabilities allow for trend analysis, helping manufacturers identify patterns in tool wear and make informed decisions about tool selection, machining speeds, and maintenance schedules. This not only improves the efficiency of individual operations but also contributes to long-term cost savings by extending tool life and minimizing unplanned downtime.

The ToolSens8 is particularly valuable when used alongside other precision tools, such as CNC tool setters, PoStep25-256 stepper motor drivers, and PCB testers. In combination, these devices create a highly efficient production environment where motion, tooling, and assembly processes are closely monitored and optimized. For example, the ToolSens8 can signal a CNC tool setter to recalibrate or compensate for minor deviations in tool position, ensuring that each cut is executed with absolute accuracy. Similarly, in automated assembly or electronics production, the insights provided by the ToolSens8 can prevent misalignments or errors that might otherwise compromise product quality.

Ultimately, the ToolSens8 serves as a critical component in modern manufacturing, bridging the gap between machine performance and production quality. By providing precise, real-time monitoring of tools, it empowers operators to maintain high standards, reduce waste, and achieve consistent results. Its role extends beyond simple measurement—it is a proactive solution that enhances operational efficiency, safeguards equipment, and supports the seamless integration of advanced tools and technologies in complex production workflows.

What is a CNC tool setter and why is it crucial for machining accuracy?

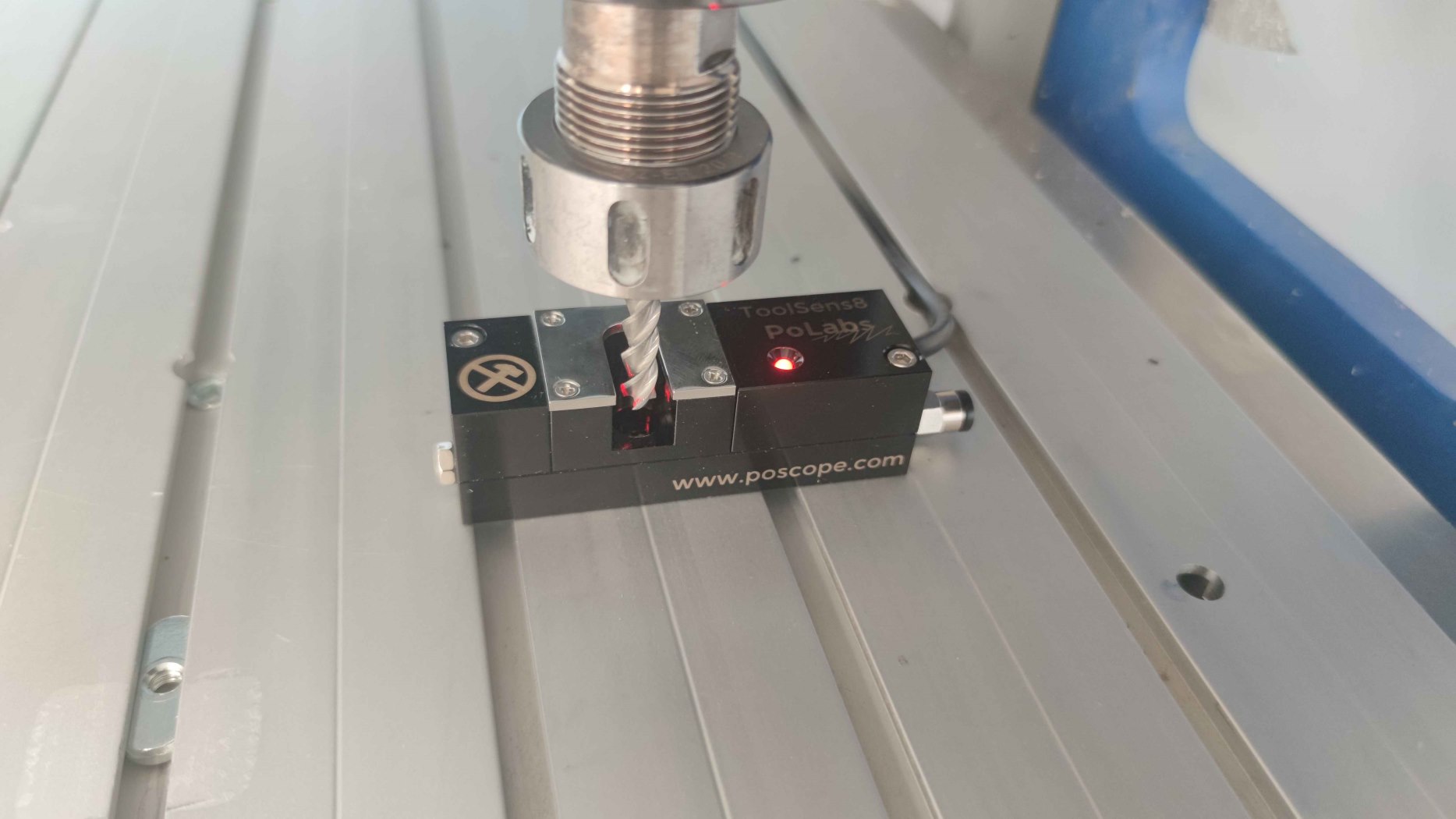

A CNC tool setter is a precision device used to measure, calibrate, and monitor cutting tools within computer numerical control (CNC) machining environments. In modern manufacturing, where tolerances are often measured in microns, ensuring that every tool is correctly positioned and precisely measured is critical for achieving high-quality results. The CNC tool setter serves this exact purpose, allowing operators to quickly verify tool lengths, diameters, and offsets, thereby reducing errors, minimizing scrap, and improving overall productivity.

The primary function of a CNC tool setter is to provide accurate and repeatable measurements of tools before they engage with the workpiece. By detecting even minor deviations in tool length or orientation, the device ensures that machining operations maintain consistent depth, alignment, and precision. This capability is particularly important in industries such as aerospace, automotive, and medical device manufacturing, where precision and reliability are non-negotiable. With a CNC tool setter, operators can prevent costly mistakes that could result from worn, broken, or improperly positioned tools, ensuring that each cut meets strict specifications.

In addition to its measurement capabilities, a CNC tool setter often integrates with CNC control systems, enabling automated tool compensation. This integration allows the machine to adjust cutting parameters in real time based on the tool’s actual dimensions, rather than relying on theoretical or pre-set values.

The result is a highly efficient process where tools are used to their full potential while maintaining precision and avoiding unnecessary wear. Many CNC tool setters also feature robust construction and advanced sensing technology, which provides reliable performance even in demanding environments with vibration, temperature fluctuations, or dust.

A CNC tool setter becomes even more effective when used in combination with other advanced tools, such as the ToolSens8 for monitoring tool condition, the PoStep25-256 stepper driver for precise motion control, and PCB testers for verifying electronics components in hybrid manufacturing processes.

By integrating these tools into a single workflow, manufacturers can create a highly synchronized and intelligent production environment. For instance, the CNC tool setter ensures the physical accuracy of tools, while the ToolSens8 monitors their condition during operation, and the PoStep25-256 guarantees precise positioning of motion systems. This synergy results in higher accuracy, fewer defects, and more efficient use of materials and machine time.

Ultimately, a CNC tool setter is indispensable for modern machining operations that demand precision, reliability, and efficiency. By providing exact measurements, enabling automated compensation, and supporting proactive maintenance, it enhances both the quality and speed of production. For manufacturers seeking to optimize their CNC processes, integrating a tool setter into their workflow is not just beneficial—it is essential for maintaining competitive performance and delivering consistently precise results.

Seeing the Signal, Understanding the Data: A Deep Dive into Oscilloscopes and I2C Decoding

Conclusion

In today’s fast-paced manufacturing and electronics environment, precision, reliability, and efficiency are no longer optional—they are essential. Tools like the PoStep25-256, PCB testers, ToolSens8, and CNC tool setters play a pivotal role in achieving these goals, each addressing a critical aspect of modern production workflows. The PoStep25-256 ensures smooth and highly accurate motion control, allowing machines to perform complex operations with consistency. PCB testers safeguard the integrity of electronic circuits, detecting faults early and preventing costly errors in assembly. The ToolSens8 provides real-time monitoring of cutting tools, enabling proactive maintenance and optimal machining performance. Meanwhile, CNC tool setters guarantee that every tool is correctly measured and positioned, maintaining exacting tolerances across even the most demanding projects.

When integrated, these technologies create a comprehensive system that maximizes productivity, reduces waste, and enhances the quality of both mechanical and electronic components. They exemplify how precision tools and intelligent monitoring can transform traditional workflows into highly efficient, reliable, and automated processes. For engineers, technicians, and manufacturers, understanding and utilizing these tools is essential not just for operational efficiency, but for maintaining a competitive edge in a rapidly evolving industry. Ultimately, the PoStep25-256, PCB testers, ToolSens8, and CNC tool setters represent more than specialized equipment—they are the foundation of modern, high-precision manufacturing and a testament to the power of technology in optimizing human ingenuity.